Electronic Contract Manufacturing Services

Manufacturing and Assembly Services

Spectra-Tech provides a wide variety of electronic manufacturing services that support the production of circuit board assemblies. Our high standards for quality, technical expertise and flexibility, exceed industry benchmarks resulting in low overhead and a cost competitive advantage.

Spectra-Tech has a highly specialized and dedicated workforce that has the experience and knowledge of electronics that is integrated into the production environment. We adapt quickly to your requirements and provide a reliable manufacturing process that includes online work instructions, defect tracking, and shop-floor tracking.

If a customer requires a custom box build, we have the in-house expertise to provide defect-free assembly including final packaging and boxing.

Kanban & Stocking Programs

Spectra-Tech offers a wide range of customized Kanban and Stocking Programs to meet our customer’s needs. We work closely with our customers to analyze their requirements. We customize programs to help them achieve increased inventory turns, just in time delivery and stocking programs for finished goods. We continuously monitor changing customer demands by utilizing forecasts and sales data to assure continuity within the supply chain.

Back To Top

Supply Chain Management

Spectra-Tech’s Supply Chain is assembled with a diversified and competitive infrastructure of worldwide manufacturers and distributers. We have integrated vendor consignment programs and utilize EDI (Electronic Data Interchange). This provides vendors electronic data that assists in synchronizing supply and demand. Vendor performance is monitored and measured regularly for continuous improvement and risk management.

Back To Top

Program Management

All customers are assigned a dedicated Spectra-Tech Program Manager who serves as the main contact for all business activity. From product introduction through delivery, your program manager will provide quality service, leadership and integrity from our cross functional team. A priority of Spectra-Tech is developing quality partnerships through responsive customer service and customized solutions while delivering high quality products for a competitive price

Back To Top

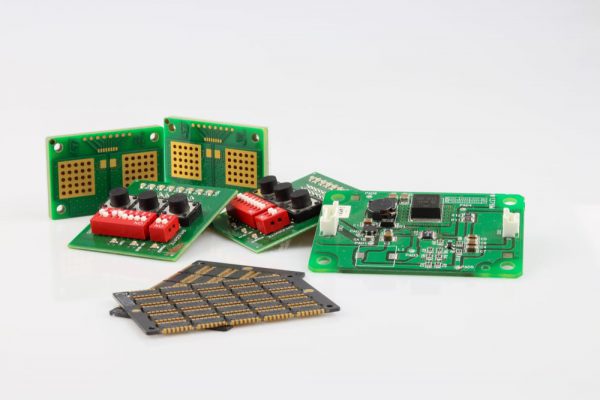

Engineering and Prototyping Services

Engineering Services

Spectra-Tech offers engineering services that will support all of your electronic manufacturing requirements. Our engineering department provides strategic information for PCB and mechanical assembly during design, prototype, and all phases of production and testing. Our Engineering Team methodically study and analyze all documentation to determine the most efficient and reliable process to assemble your products to precise standards.

Design for Manufacturability (DFM)

Spectra-Tech provides its customers Design for Manufacturability (DFM) services as a value-added advantage. This includes a review of the component technology, component placement options, PCB arrays, processing options and bill of material (BOM) selections. This information will be communicated to our customer with recommendations to ensure the most cost-effective and reliable manufacturing processes are employed.

Documentation Control & Process Engineering

Spectra-Tech develops detailed customer assembly documentation and machine programs by utilizing Aegis Factory Logix Software. This software provides an accurate high-speed method to rapidly process all assembly documents and machine programs. Our Engineering Team determines the most reliable and efficient methods to manufacture our customers products in accordance with your requirements and latest industry standards.

Customer BOM to layout data verification

Process and Specification Review

Revision Controls – Paperless documentation system

Additionally, creating documentation , machine programs, fixtures, thermal profiles for production, specialized processes and procedures, will be developed as necessary, depending on the unique requirements of your project.

Prototyping

Spectra-Tech provides prototyping services to assist and help our customers verify their design requirements. Our Engineering Team works closely with our customers on prototype builds to confirm the technical layout of the product provides the most cost-efficient option. We will deliver the necessary units for your approval and assess what steps are necessary to move your product to a full production phase.

Back To Top

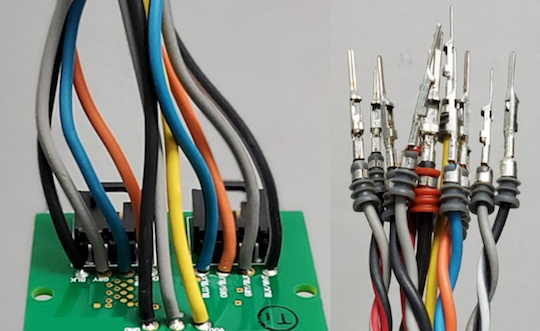

Wire Harness, Cable Assembly, and Overmolding Services

View Samples of Spectra-Tech’s Cabling Capabilities

Click here for PDF Document of Spectra-Tech Samples

If you are looking for a customized solution for Wire Harnesses, Cable Assemblies or Overmolding Services, simply supply us with your specifications and we can handle the rest.

We offer our cabling service for standalone individual orders or we can also provide customers with the value-added service of soldering directly onto your PCB assembly orders.

If your wire assemblies need to be more durable and withstand various environments, we recommend our Overmolding Service. Not only does Overmolding give your product a more aesthetically pleasing appearance, it also will provide more support during flexing and handling.

Back To Top

Contact Us